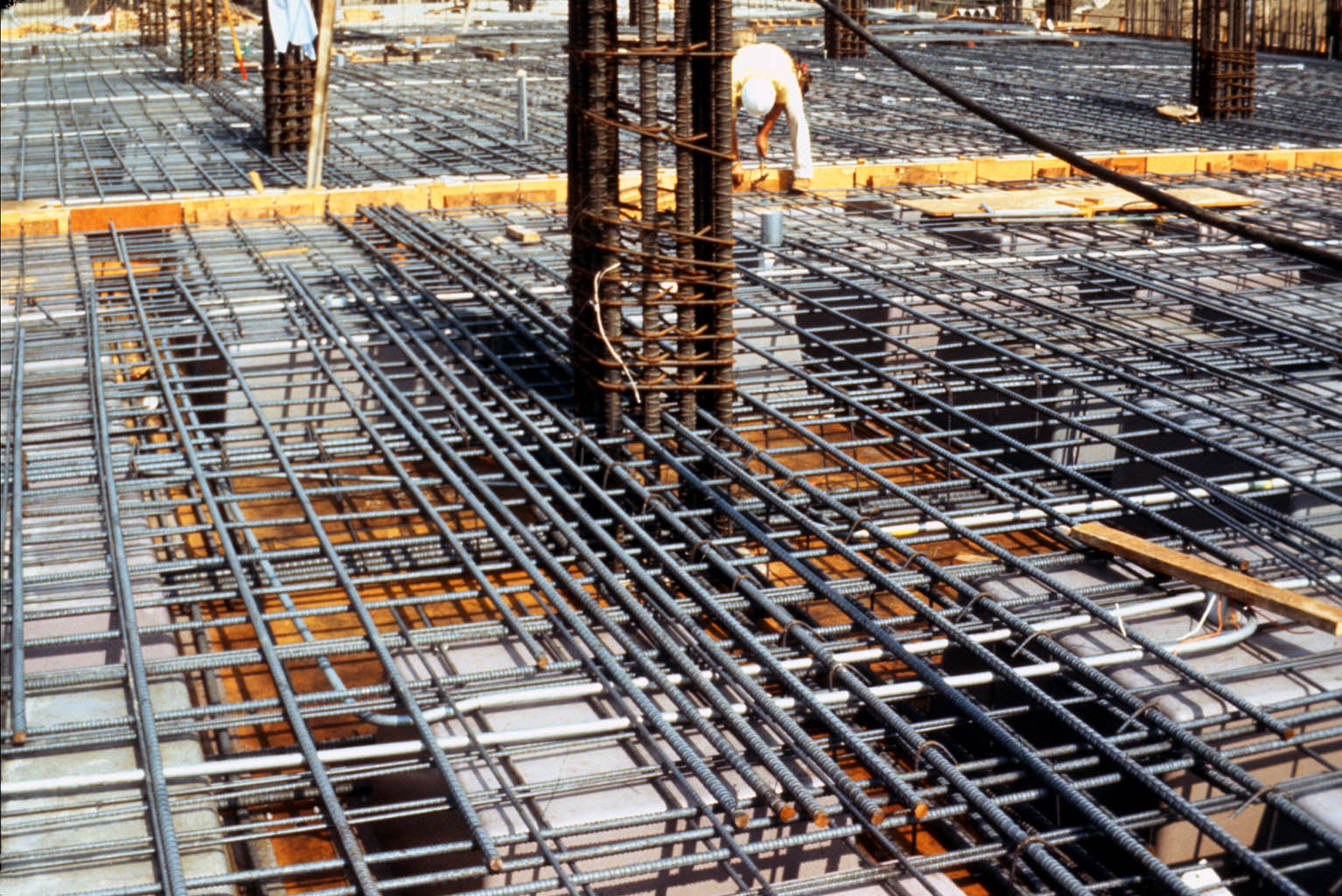

Reinforcing bars help concrete to withstand tension. Concrete is naturally strong enough to withstand compressive forces, but tensile forces can cause it to crack.

The deformed pattern on a rebar helps the concrete adhere to the reinforcing steel surface. The pattern on a deformed bar isn’t specified, but the spacing and the height of the “bumps” are regulated.

Different Steel Bars Used in Construction

1. Carbon Steel Rebars:

This is the most common type of reinforcement and is sometimes referred to as “black bars.” It has a wide range of uses, but it is easier to corrode than other types, making it unsuitable for use in high humidity environments or structures that are frequently exposed to water. However, it is believed that carbon steel rods are the best choice for all other types of structures.

2. Welded Wire Fabric:

Welded wire mesh (WWF) consists of a series of steel wires arranged at right angles and is electrically welded at all intersections of the steel wires. It can be used on ground slabs with dense soil. Heavier welded wire boards can be used for walls and structural floors. It is widely used in sidewalks, culverts, drainage structures and small concrete passages.

3. Sheet-Metal Reinforcing Bars:

Sheet metal reinforcements are usually used in the construction of floors, stairs and roofs. The sheet metal reinforcement is made of annealed sheet steel that are bent into shafts approximately one-sixteenth of an inch deep and holes are drilled at regular intervals.

4. Epoxy Coated Rebars:

Epoxy-coated rebars are expensive and used in areas that will be in contact with salt water or where a corrosion problem is imminent. The only problem is that the coating can be very delicate, so bars should be ordered from a reputable supplier.

5. Stainless Steel Rebars:

Stainless steel can replace carbon steel rebar. The use of stainless-steel fittings will not cause galvanic corrosion, and may be a cost-effective solution in areas where corrosion problems or maintenance are difficult and expensive.

6. Galvanized Rebars:

Galvanized rebars are 40 times more resistant to corrosion than carbon steer rebars, making them ideal for structures that will be heavily exposed to wet and humid conditions. However, they’re costly.

7. Expanded Metal or Wire Mesh Rebars:

Expanded metal or wire mesh reinforcement is another good product for concrete. Expanded metal is made by shearing a sheet of steel into parallel lines that are then expanded to form a diamond shape or a square shape between each cut. Expanded metal is commonly used as reinforcement in areas where a considerable thickness of plaster is required, or to reinforce light concrete construction. Wire mesh reinforcement can be used on sidewalks, small concrete pads, or walkable surfaces that don’t receive high live or load charges.

8. Glass-Fiber- Reinforced-Polymer (GFRP) Rebars:

Similar to carbon fiber, GFRP rebars will not corrode — ever, under any conditions. You’ll pay dearly for that, however. These rebars can run 10 times the cost of epoxy-coated rebars.